Polymer Bearing Market: Global Industry Overview and Forecast (2024-2030) Trends, Dynamics, Segmentation

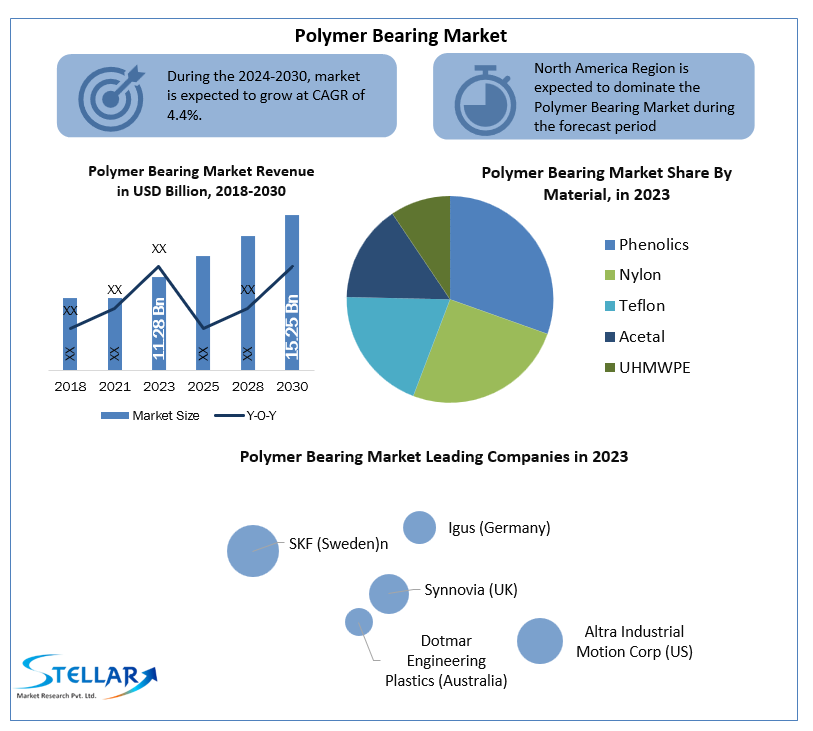

Polymer Bearing Market size was valued at US$ 11.28 Bn. in 2023 and the total revenue is expected to grow at 4.40% through 2024 to 2030, reaching nearly US$ 15.25 Bn. by 2030.

Format : PDF | Report ID : SMR_1030

Polymer Bearing Market Overview:

Polymer bearings are attractive because they can withstand harsh environments that can damage normal bearings. Polymeric materials are 80% lighter than steel. As a result, bearings made from polymers require less energy to move and are less likely to lose strength due to collisions. Polymer bearings, compared to metal bearings, are better alternatives for economic growth and are 70 to 80% lighter compared to other metals and thus are commonly used in the automotive industry. Polymer bearings have made a name for themselves in the competitive carrier market by offering a few advantages. As a result, areas that did not represent steel- and phosphorus-bronze-bronze are increasingly filled with polymers such as PTFE, PEEK, POM, and Nylon.

Polymer Bearing Market report examines the market's growth drivers and segments (Conductive Material, Application, End-User, and Region). Data has been provided by market participants and regions (North America, APAC, Europe, MEA, and South America). This market study takes an in-depth look at all of the significant advancements occurring across all industry sectors. To provide key data analysis for the historical period (2018-2022), statistics, infographics, and presentations are used. The report examines the Polymer Bearing markets, Drivers, Restraints, Opportunities, and Challenges. This SMR report includes Polymer Bearing investor recommendations based on a detailed analysis of the current competitive landscape of the Polymer Bearing market.

To get more Insights: Request Free Sample Report

COVID-19 pandemic on the Polymer Bearing Market:

The economic impact of COVID-19 on used industries has finally been enormous. Travel restrictions have caused the decline of many markets, and growth has slowed as a result. The closure of the facilities has forced production facilities to remain closed, with a negative impact on the polymer holding market due to the loss of revenue due to the low acceptance of polymer solutions across industries. All major industries are facing disruptions, such as supply chain failure, technological adoption, and office closures. Since the removal of travel restrictions, growth in all markets has gained tremendous strength.

Disruption of supply chain operations delayed vehicle production and thus hampered the growth of the global polymer bearing market. In addition, declining demand in the automotive industry has been caused by the COVID-19 epidemic, which is affecting the growth of the polymer bearing market.

Polymer Bearing Market Dynamics:

Increasing demand in the automotive industry is expected to boost the polymer bearings market worldwide due to the various characteristics of these bearings, such as their oil-free nature, high corrosion resistance, and resistance to fatigue. The increasing use of polymer bearings in end-of-life industries such as textiles, packaging, food, and packaging enhances the growth of the global polymer bear market. In addition, polymer bearings are needed in many different industries due to their excellent low friction and high wear resistance.

In addition, advances in 3D printing technology are expected to create opportunities for growth in the global polymer market. Custom 3D blank bearings developed from efficient polymers last longer than standard 3D printing materials. 3D printing gives producers a way to design, creating bearings with enhanced functionality. The growing popularity of 3D printing is expected to increase the use of polymer bearings in all industries.

In addition, polymer bearings can withstand high operating temperatures and maintain their mechanical properties than babbitt. Polymers are resistant to many chemical attacks, including hydrogen sulfide and ammonia, which protect the bearings from damage when in contact with these chemicals. The reduced weight of the polymer bearings makes all construction easier, leading to higher performance and less carbon dioxide emissions.

A collision occurs when parts of a machine come together. Polymer bearings reduce the coefficient of friction and result in less aging and quieter performance. Technological advances and the growth of R&D investment create opportunities for growth in the global polymer market. In addition, the growing demand for polymer bearings in the automotive and aerospace industries are expected to grow the market. Polymer bearings provide an inexpensive alternative to steel bearings, reducing repair costs and opening up opportunities for technological development.

Polymer Bearing Market Segment Analysis:

by Material

Phenolics: Phenolic compounds include cotton fabric or other fillers mixed with phenolic resin. These compounds are easily absorbed into various liquids, making them ideal for automotive use. Due to their high strength and low weight, phenolic bearings are famous for replacing steel bearings on propeller bearings and rubber-shaft on ships as well as electric switch-gear, rolling-mill, and water-turbine bearings. Phenolic laminates act as structural components and carriers in small tools and clock mechanisms. Phenolic bearings are durable, resistant to shock and water, acid, and alkaline solutions, and work well on heavily loaded systems that provide adequate clearance and cooling.

Nylon: Although phenolics are used in hard work, they are often replaced by nylon, which finds its widespread use in bearings. Nylon trees do not require anointing and have low friction. Nylon is a strong, quiet material that can withstand scratches when used and can wear out slightly. It is easily shaped, cast, or machine-made to fit very closely. Applying a thin line of material to a well-supported steel sleeve can reduce cold flow problems at high loads.

Teflon: Teflon is a good material for bearings because it provides low friction, high wear resistance, resistance to multiple chemical attacks, and can operate at wide temperatures. The load capacity of Teflon bearings depends on how well they are constructed and reinforced. Teflon bearings are excellent for exposure to weather, chemicals, and the use of vapor. Teflon bearings suitable for applications such as sluice gates need to work efficiently, reliably, and without adherence after a long period of inactivity. Apps that include low rpm, oscillatory, or temporary service, as well as reliable non-slip service are essential, can benefit from Teflon bearings. The biggest drawback of using Teflon bearings is its high cost compared to other bearings.

Acetal: Acetal is a popular carrier material in many automotive, electrical, and industrial applications. It is beneficial when working in wet areas due to its stability and resistance to wet abrasions.

UHMWPE (Ultra High Molecular Weight Polyethylene): UHMWPE bearings are generally a good alternative to acetal, nylon, and Teflon bearings that are resistant to abrasion and have a smooth, low-impact surface.

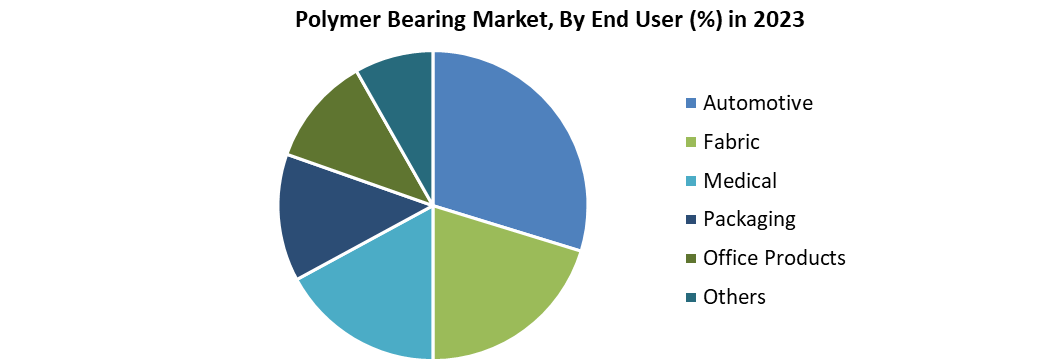

Polymer Bearing Market, by End User

Automotive: The cost benefits of polymer solutions are very important in the automotive industry. Polymer bearings are particularly durable, require little care, and provide thermal stability, the most important attributes in the automotive industry. Polymer bearings are lighter than steel, resulting in less fuel consumption and a wider range. Polymer bearings do not require additional oil or lubrication, nor do they care.

Fabric: Fabric machinery is increasingly widely used, increasing the demand for sturdy machine parts. Vibration, various operating conditions, changes in loads, and especially dirt and dust are challenges that plant operators in the textile industry face. In addition, textile manufacturers should not ignore external factors such as humidity and temperature fluctuations. Therefore, repair work is difficult to plan and is only done over a long period of time. Polymer bearings made of highly efficient polymers do not require additional coating and have a long service life and meet all the requirements of the textile industry.

Medical: Medical technologies use bearings to control high speed and high level of hygiene. In the medical field, where cleanliness is a major concern, unadulterated balls have an important role to play. Polymer bearings, unlike metal bearings, do not require lubrication, so they are ideal for applications where sterility and suitability for a clean room are required.

Packing: Polymer bearings have many applications in the packaging industry. Dry working polymer bearings that do not require repair or lubrication reduce the risks of mechanical contamination. Polymer bearings enable manufacturers to predict the life of machines, to adjust the performance of repairs, and to reduce shrinkage times.

Office Products: Non-greasy, careless, and inexpensive polymer products ensure the efficient operation of office products.

Other: Other uses of polymer bearings include food processing, elevators, photography, chemicals, and electronics.

Polymer Bearing Market Regional Insights:

The North American region of the polymer market is driven by a growing industrial sector in the region. The North American market is driven primarily by the growing demand for polymer bearings in the healthcare and manufacturing sectors. The development of polymers in handling applications drives the need for polymer bearings in this region. While, the European market is expected to meet the high demand for polymer bearings due to the growth of the automotive, textile, and cosmetics industries in the region. The main contributors to market growth include Germany, the UK, France and Russia.

While, Asia-Pacific dominates the global polymer market due to the rapid growth of industry in the region. Growth potential in developing economies such as China, India, South Korea. The Asia-Pacific polymer bearings market has been experiencing steady growth due to the growing demand for polymer bearings in the food and beverage, delivery and transportation industries. Asia-Pacific held the largest share in the polymer bearing market in 2023 up to 30%, it is due to increase in demand for polymer bearings in APAC region from various end-use industries.

The objective of this report is to present an in-depth analysis of the Polymer Bearing Market to industry stakeholders. The report provides the recent trends in the Polymer Bearing Market and how these factors will impact on new business investment and market enhancement during the forecast period. The report also provides an understanding of the potential of the Polymer Bearing Market and the competitive structure of the market by analysing market leaders, market fans, and regional players.

The quality and quantity data provided in the Polymer Bearing Market report assist the readers to understand which market Conductive Materials, regions are expected to grow in value, market factors, and key opportunity areas, which will impact industry growth and predictable market growth with respect to time. The report includes the competitive status of key competitors in the industry and their recent developments in the Polymer Bearing Market. The report also provides a comprehensive set of factors such as company size, market share, market growth, revenue, production capacity, and profits of key players in the Polymer Bearing Market.

The report provides Porter's Five Force Model, which helps in designing the business strategies in the market. The report helps in identifying how many rivals are existing, who they are, and how their product quality is in the Market. The report also analyses if the Polymer Bearing Market is easy for a new player to gain an edge in the market, do they come and go in the market regularly if the market is dominated by a few players, etc.

The report also includes a PESTEL Analysis, which aids in the development of company strategies. Political factors that help in analysing how much a government can impact the Market. Economic variables assist in the calculating economic performance drivers that can affect the Market. Analysing the impact of the overall environment and the impact of environmental concerns on the Polymer Bearing Market is aided by legal factors.

Polymer Bearing Market Scope:

|

Polymer Bearing Market |

|

|

Market Size in 2023 |

USD 11.28 Bn. |

|

Market Size in 2030 |

USD 15.25 Bn. |

|

CAGR (2024-2030) |

4.40% |

|

Historic Data |

2018-2022 |

|

Base Year |

2023 |

|

Forecast Period |

2024-2030 |

|

Segment Scope |

By Material

|

|

|

By End User

|

|

|

North America- United States, Canada, and Mexico Europe – UK, France, Germany, Italy, Spain, Sweden, Austria, and Rest of Europe Asia Pacific – China, India, Japan, South Korea, Australia, ASEAN, Rest of APAC Middle East and Africa - South Africa, GCC, Egypt, Nigeria, Rest of the Middle East and Africa South America – Brazil, Argentina, Rest of South America |

Polymer Bearing Market Key Players

- SKF (Sweden)n

- Igus (Germany)

- Synnovia (UK)

- Altra Industrial Motion Corp (US)

- Dotmar Engineering Plastics (Australia)

- Saint-Gobain (France)

- OILES CORPORATION (Japan)

- Kashima Bearings, Inc. (Japan)

- KMS Bearings, Inc. (US)

- TOK, inc. (Japan)

- Xinzhou Bearing Industrial Inc. (China)

- Waukesha Bearings (US)

- ISB Industries (Italy)

- BNL Ltd (UK)

- Kilian Manufacturing (US)

Frequently Asked Questions

Fabric are the leading type of end user segment of Polymer Bearing market.

The market size of the Polymer Bearing is expected to reach by USD 15.25 Bn. in Polymer Bearing Market.

The forecast period of Polymer Bearing market is 2024-2030

Acetal are the leading type of Material segment of Polymer Bearing market.

- Scope of the Report

- Research Methodology

- Research Process

- Global Polymer Bearing Market: Target Audience

- Global Polymer Bearing Market: Primary Research (As per Client Requirement)

- Global Polymer Bearing Market: Secondary Research

- Executive Summary

- Competitive Landscape

- Market Share Analysis by Region in 2023 (%)

- North America

- Europe

- Asia Pacific

- Middle East and Africa

- South America

- Stellar Competition matrix

- Global Stellar Competition Matrix

- North America Stellar Competition Matrix

- Europe Stellar Competition Matrix

- Asia Pacific Stellar Competition Matrix

- South America Stellar Competition Matrix

- Middle East and Africa Stellar Competition Matrix

- Key Players Benchmarking: - by Product, Pricing, Investments, Expansion Plans, Physical Presence, and Presence in the Market.

- Mergers and Acquisitions in Industry: - M&A by Region, Value, and Strategic Intent

- Market Dynamics

- Market Drivers

- Market Restraints

- Market Opportunities

- Market Challenges

- PESTLE Analysis

- PORTERS Five Force Analysis

- Value Chain Analysis

- Market Share Analysis by Region in 2023 (%)

- Global Polymer Bearing Market Segmentation

- Global Polymer Bearing Market, by region (2023-2030)

- North America

- Europe

- Asia-Pacific

- Middle East & Africa

- South America

- Global Polymer Bearing Market, by Material (2023-2030)

- Phenolics

- Acetal

- Nylon

- Teflon

- UHMWPE

- Global Polymer Bearing Market, by End User (2023-2030)

- Automobile

- Fabric

- Medical

- Packaging

- Office Products

- Others

- Global Polymer Bearing Market, by region (2023-2030)

- North America Polymer Bearing Market Segmentation

- North America Polymer Bearing Market, by Material (2023-2030)

- Phenolics

- Acetal

- Nylon

- Teflon

- UHMWPE

- North America Polymer Bearing Market, by End User (2023-2030)

- Automobile

- Fabric

- Medical

- Packaging

- Office Products

- Others

- North America Polymer Bearing Market, by Country (2023-2030)

- United States

- Canada

- Mexico

- North America Polymer Bearing Market, by Material (2023-2030)

- Europe Polymer Bearing Market Segmentation

- Europe Polymer Bearing Market, by Material (2023-2030)

- Europe Polymer Bearing Market, by End User (2023-2030)

- Europe Polymer Bearing Market, by Country (2023-2030)

- Asia Pacific Polymer Bearing Market Segmentation

- Asia Pacific Polymer Bearing Market, by Material (2023-2030)

- Asia Pacific Polymer Bearing Market, by End User (2023-2030)

- Asia Pacific Polymer Bearing Market, by Country (2023-2030)

- Middle East and Africa Polymer Bearing Market Segmentation

- Middle East and Africa Polymer Bearing Market, by Material (2023-2030)

- Middle East and Africa Polymer Bearing Market, by End User (2023-2030)

- Middle East and Africa Polymer Bearing Market, by Country (2023-2030)

- South America Polymer Bearing Market Segmentation

- South America Polymer Bearing Market, by Material (2023-2030)

- South America Polymer Bearing Market, by End User (2023-2030)

- South America Polymer Bearing Market, by Country (2023-2030)

- Company Profiles

- Key Players

- SKF (Sweden)

- Company Overview

- Product Portfolio

- Financial Overview

- Business Strategy

- Key Developments

- SKF (Sweden)

- Key Players

-

-

- Igus (Germany)

- Synnovia (UK)

- Altra Industrial Motion Corp (US)

- Dotmar Engineering Plastics (Australia)

- Saint-Gobain (France)

- OILES CORPORATION (Japan)

- Kashima Bearings, Inc. (Japan)

- KMS Bearings, Inc. (US)

- TOK, inc. (Japan)

- Xinzhou Bearing Industrial Inc. (China)

- Waukesha Bearings (US)

- ISB Industries (Italy)

- BNL Ltd (UK)

- Kilian Manufacturing (US)

-

- Key Findings

- Recommendations